Growing the future

Ryan completed an apprenticeship in architecture at the age of 16. After completing an ONC in Building Studies, he spent 13 years working for an architectural practice in North Yorkshire. Much of the work that he poured his heart and soul into came to nothing, which is why he decided to switch to something a little more fast-paced.

Steel manufacturing was the tonic he needed. Joining a company in Leeds, he had produced a drawing in the morning, and by the afternoon the product was being made. Whilst he was there, he met future Magical Mushroom Company Founder, Paul Gilligan. Over the years, Ryan worked with Paul on various product design projects, so when Paul needed some eco-friendly packaging designs, Ryan was the obvious choice.

It was the opportunity Ryan had been waiting for. A chance to do something proper in the world – much more than just a nice idea on paper.

Mycelium uncovered

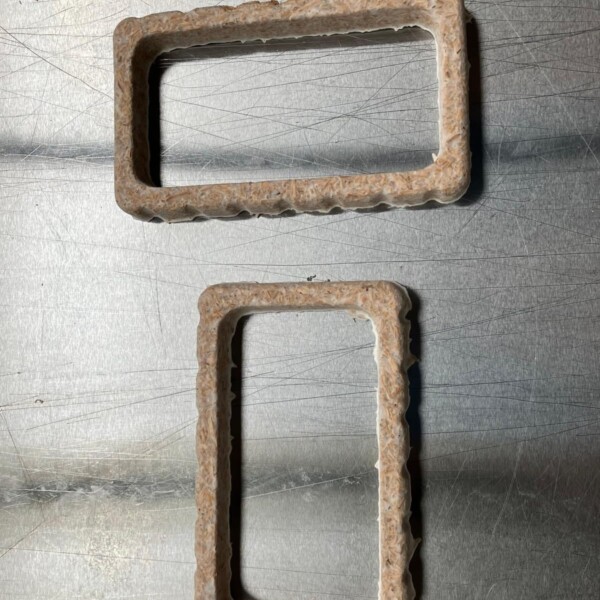

Mycelium is the root structure that exists beneath a mushroom. Combine that with agricultural waste and leave it to ‘grow’ in the ideal conditions, and you get a substance suitable for packaging.

It’s a concept pioneered by a company based in New York – Ecovative – who demonstrated its commercial viability to Ryan and his co-collaborators. It was a first glimpse of the industrial scalability of mycelium, and its potential to eliminate the global need for polystyrene.

Interestingly, packaging design itself is not the biggest barrier to product development. Even the most outwardly eco-conscious businesses can baulk at a fractional price increase. Some of that is due to legacy attitudes towards packaging – it doesn’t directly add any value to a product – it just gets thrown away.

With mycelium packaging, you simply put it in your food waste bin or a composter, instead of throwing it away. It fully disappears within weeks. There are even competitive stories circulating about how quickly it decomposes!

Mycelium and sustainable wayfinding

The most obvious commercial example, and validated use-case, is swapping out the polystyrene used to package furniture like kitchen cabinets, for mycelium. It’s a straight swap.

Right now, we’re into the millions for the number of packaging parts that have been replaced by mycelium. One place mycelium packaging can make the biggest difference is for household items like white goods.

But could sustainable wayfinding signage be another viable use case?

Signs are typically built to last 5 to 15 years. That’s why Endpoint recently set itself a challenge to seamlessly blend highly-sustainable materials into product design, without compromising on quality and efficiency.

It’s not as left-field as it sounds. Ryan’s business – Funguy – has been approached by many people with niche ideas for the application of mycelium. The opportunities are as fascinating as they are diverse, including architecture and interiors – especially in the field of temporary signage and temporary structures.

In fact, the ideal application is when the lifespan of the material matches the time frame for the job it’s designed to do – like festival signage, for example. After the event, it’s simply left to biodegrade.

One of the biggest challenges of mycelium is educating people about what it can, and can’t do. There’s a myth that it’s produced in sheets which can be moulded into anything you want, and simply used to replace existing non-sustainable materials. The reality is that it’s only recently become commercially consistent.

A world of opportunity

Mycelium will eventually be used to make many different kinds of objects. Its transient nature rules out some potential applications, but it’s an ideal material for anything with a limited shelf life – like visual merchandising in retail stores.

Mycelium has a unique look and feel, a super-soft texture, a bit like a rabbit’s ear. The substrate used for making mycelium requires the same agricultural by-product and genus of mycelium, which gives it a consistent colour.

By changing the genus of mushroom, it’s possible to generate different colours, which can even be altered via certain lighting conditions. However, all of this development is still in the early stages.

Advice for businesses

It’s great that companies want to use the mushroom-based material, but it’s not always the best fit for certain projects. That’s why it’s valuable to speak to someone like Ryan – an expert in the field of micro-composites – who can advise on the best solution. In the future, Ryan’s long term goal is to eliminate the use of polystyrene wherever possible and replace it with more appropriate – and sustainable – types of packaging.

For more information about Ryan Little's work with mycelium, feel free to reach out to him at ryan@funguy.co.uk.